Product Labeling Solutions: Shrink Sleeves vs. Pressure-Sensitive Labels

Product labeling solutions are essential tools that provide your customers with crucial information about the items they’re purchasing. From nutrition facts and expiration dates to usage instructions and proper disposal methods, the different parts of a product label deliver important details that help consumers make informed decisions.

When choosing the right product labeling solution for your primary packaging, two compelling options stand out: pressure sensitive labels and shrink sleeves. But which one better suits your specific needs? This article will help you understand the differences between these two popular product labeling solutions and provide practical examples to guide your decision.

What are Shrink Sleeves?

Shrink sleeves are a dynamic labeling for packaging solution that offers an eye-catching way to showcase your product information. Made from materials like PETG or PVC, these sleeves are designed to fit snugly around containers of various shapes.

The application process involves slipping a printed sleeve over the container and then using specialized heat equipment to shrink the sleeve, creating a perfect fit that conforms to the container’s unique shape. This method provides seamless, 360-degree coverage, making shrink sleeves particularly effective for products with complex shapes or those requiring extensive branding opportunities.

Benefits of Using Shrink Sleeves as Custom Product Labels

Shrink sleeves offer several advantages as a product labeling solution and can serve as highly visual custom product labels:

- 360-degree coverage

- Enhanced durability

- Tamper-evident sealing

- Cost efficiency

- Versatility

This widespread use highlights their effectiveness as specialized product labeling solutions for unique types of product labels and packaging demands.

Industries That Use Shrink Sleeve Labels

Shrink sleeve labels are widely adopted across industries where bold visuals and durability are priorities:

- Food and beverage

- Pet care

- Pharmaceuticals and nutraceuticals

- Home and personal care

- Cosmetics

- Automotive products

This widespread use highlights their effectiveness as specialized product labeling solutions for specific packaging demands.gments.

Shrink Sleeve Labels in Detail

These are ideal for promotional packaging, multi-version products, and items with unique container shapes—making them a flexible product labeling solution and strong option within the many types of product labels available today.

What Makes Shrink Sleeves Unique?

Shrink sleeves are full-color labels created from polymer films. The manufacturing process involves printing on a digital press, seaming the material with openings at the top and bottom to create a “sleeve,” and then wrapping this sleeve around the product container. When heat is applied, the sleeve shrinks to match the container’s contours, providing complete 360-degree coverage.

Full-body shrink sleeves deliver seamless, tamper-evident packaging with comprehensive visibility of branded graphics. This printing technique creates labels that not only conform perfectly to container shapes but also catch consumers’ attention with vibrant product label designs.

Shrink sleeves excel for promotional items, press proof samples, prototypes, and products requiring multiple versions. They’re commonly found on food, beverage, pharmaceutical, automotive, home, pet care, and skincare products.

Pros and Cons of Shrink Sleeves as Product Labeling Solutions

Pros:

- Durable and moisture-resistant: Ideal for products exposed to wet or harsh conditions.

- Great for bundling and promotions: Can wrap multiple items together securely.

- Recyclable (with proper materials): Some shrink sleeves, like those made from PETG, can be recycled if separated correctly—supporting sustainable label options in packaging strategies.

Cons:

- Graphics may distort during application if label designs aren’t adjusted for shrinkage.

- Require specialized heat equipment, increasing setup costs and complexity.

- Longer lead times compared to pressure-sensitive labels due to custom sizing and printing.

- Less flexibility for small runs or frequent changes, making them less ideal for product lines that rotate frequently.

- Challenging to recycle in mixed-stream facilities without proper material identification or removal steps.

- Higher per-unit costs than pressure-sensitive labels, especially for brands with simpler packaging needs.

Pressure-Sensitive Labels

Understanding Traditional Labels

Pressure-sensitive labels are one of the most versatile and widely used product labeling solutions across virtually every industry and packaging format. These custom product labels consist of four key layers that work together to ensure reliable performance:

- Liner: A release layer that protects the adhesive until the label is ready to be applied.

- Adhesive: Bonds the label to the container’s surface and is available in permanent, removable, or specialty formulas—such as wash-off labels designed for easy recycling.

- Face stock: The visible part of the label, which can be made from paper, film, or other materials depending on the application.

- Topcoat: A protective layer that enhances durability and print quality, often used to add finishes like gloss, matte, or tactile effects.

These labels can be applied manually, semi-automatically, or fully automatically. This makes them a smart, scalable choice for brands seeking efficient, high-quality labeling for packaging that supports a wide variety of types of product labels. Their design flexibility allows for a wide range of shapes, sizes, and materials, making pressure-sensitive labels adaptable to nearly any container type, including flat, curved, or squeezable surfaces.

In addition to their ease of use, pressure-sensitive labels can support a variety of printing methods—including digital and flexographic—allowing for everything from short-run customization to high-volume consistency. This makes them a smart, scalable choice for brands seeking efficient, high-quality product labeling solutions.

Pros and Cons of Pressure-Sensitive Labels as Product Labeling Solutions

Pros:

- Easy to apply: Can be applied by hand or with basic equipment—no heat or solvents required.

- Versatile across container types: Works on glass, plastic, metal, and more.

- Cost-effective: Lower setup and production costs, especially for small to mid-sized runs.

- Quick turnaround: Fast to produce and easy to change between product lines.

- Ideal for short runs and frequent updates: Perfect for seasonal products, samples, or limited editions.

- Compatible with sustainable materials: Can be produced using recyclable or compostable facestocks and adhesives, aligning with modern sustainable label options.

- High print quality and customizability: Supports detailed graphics, finishes, and custom shapes.

Cons:

- Less durable in wet environments without added protection like overlaminates or specialized facestocks.

- Limited coverage: Typically covers part of the container, not offering full 360-degree branding like shrink sleeves.

Cost Comparison: Shrink Sleeves vs. Pressure-Sensitive Labels

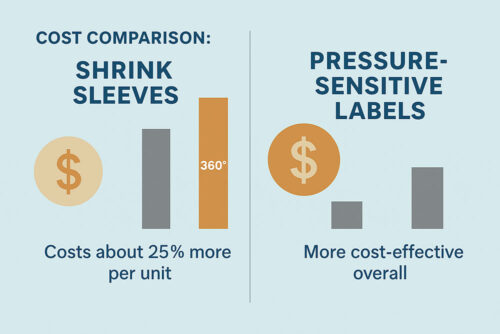

Shrink sleeves may cost about 25% more per unit but offer up to 150% more branding space with full 360-degree coverage. This makes them appealing for premium products or packaging with complex shapes. However, that added visual impact comes with additional costs—including specialized heat application equipment, longer setup times, and more complex design requirements.

In contrast, pressure-sensitive labels are typically the more cost-effective product labeling solution overall. Their flexibility supports efficient labeling for packaging, especially when managing multiple SKUs or seasonal variations in custom product labels. Changeovers are quicker, production downtime is minimal, and waste is generally lower due to easier material handling.

While the price-per-label might be lower or comparable depending on materials used, the total cost of ownership is often significantly less with pressure-sensitive labels. Their flexibility also helps brands streamline multiple product lines using a single labeling system, which can drive further cost efficiencies over time.

For companies seeking a balance of quality, branding potential, and operational simplicity, pressure sensitive labels deliver excellent value—especially when speed to market and packaging agility are key priorities.

Environmental Impact of Product Labeling Solutions

Shrink sleeves can contribute to sustainable labels when made from recyclable materials such as PETG and when designed for easy removal during the recycling process. Some shrink sleeve films are even engineered for recyclability, but they still present challenges. Because they cover the entire container, they can interfere with optical sorting in recycling facilities unless properly separated—and not all materials are accepted in standard recycling streams.

On the other hand, pressure sensitive labels are increasingly being designed as part of sustainable product labeling solutions, making them one of the more responsible types of product labels for brands with eco-conscious goals. Advances in label facestocks, adhesives, and topcoats have made it possible to use recyclable or compostable materials without sacrificing performance. For example, wash off labels—a type of pressure-sensitive label with specialized adhesives—can cleanly separate from PET bottles during the recycling process, enabling more efficient recovery of both label and container materials.

Pressure-sensitive labels also use less material overall compared to shrink sleeves, reducing packaging weight and waste. Their simpler construction and partial coverage make them easier to manage in recycling systems—key characteristics of sustainable label options.

Ultimately, the sustainability of any product labeling solution depends on careful material selection, application processes, and end-of-life planning. Brands committed to reducing their environmental footprint often find that pressure-sensitive labels offer a more straightforward path to meeting recyclability goals—especially when working with experienced partners who prioritize sustainable product label design.

Selecting the Right Label for Your Product

Each product labeling solution has strengths:

Shrink Sleeves Are Ideal For:

- Complex container shapes

- Tamper-evident packaging

- Full-wrap branding

Pressure-Sensitive Labels Are Ideal For:

- Simpler, more cost-efficient labeling

- Flexible production lines

- A wide variety of industries and product types

Evaluate your product, goals, and budget to determine the best fit.

Labeling Done Right with Meyers

As a mid-sized family business with over 70 years of experience, Meyers delivers custom product labels and product labeling solutions that help your brand stand out. While we don’t produce shrink sleeves, our expertise in pressure-sensitive labels ensures your packaging performs across every metric: durability, efficiency, and shelf appeal.

Our printing technologies—including digital, flexographic, and hybrid—allow us to tailor the right product labeling solution to your needs. Whether you’re launching a new line or scaling an existing product, Meyers offers the flexibility, sustainability, and quality you can count on for your next labeling for packaging project.

Looking for the best product labeling solution? Contact Meyers to see if pressure sensitive labels are a fit for your packaging needs.